Capabilities:

-

Horizontal Milling

The horizontal milling process involves cutting material along the X-axis, which is the horizontal plane. This cutting action is accomplished by using a rotating cutting tool, such as an end mill, that moves across the material, removing small chips of material with each pass.

Horizontal milling is applicable in creating both 2D and 3D parts and is highly in demand in the fabrication of aerospace and medical components. Horizontal milled parts can also be heat treated, anodized, or plated for added durability.

View Horizontal Services -

Milling

Milling is a CNC machining process that uses rotary cutters to remove material from a workpiece. The cutting action of the milling machine produces flat surfaces, angular shapes, and contoured profiles. Milling is common in the following industries:

- Aerospace

- Automotive

- Medical

- Electronics

Materials that undergo milling include metals, plastics, and composites. The milling process's size and complexity depending on the workpiece's size, type, and desired finish.

In most cases, milling uses computer-controlled equipment that positions the cutting tools to create the desired shape. Milling is an essential manufacturing process that helps to produce precision parts and products with a wide range of applications.

View CNC Milling Services -

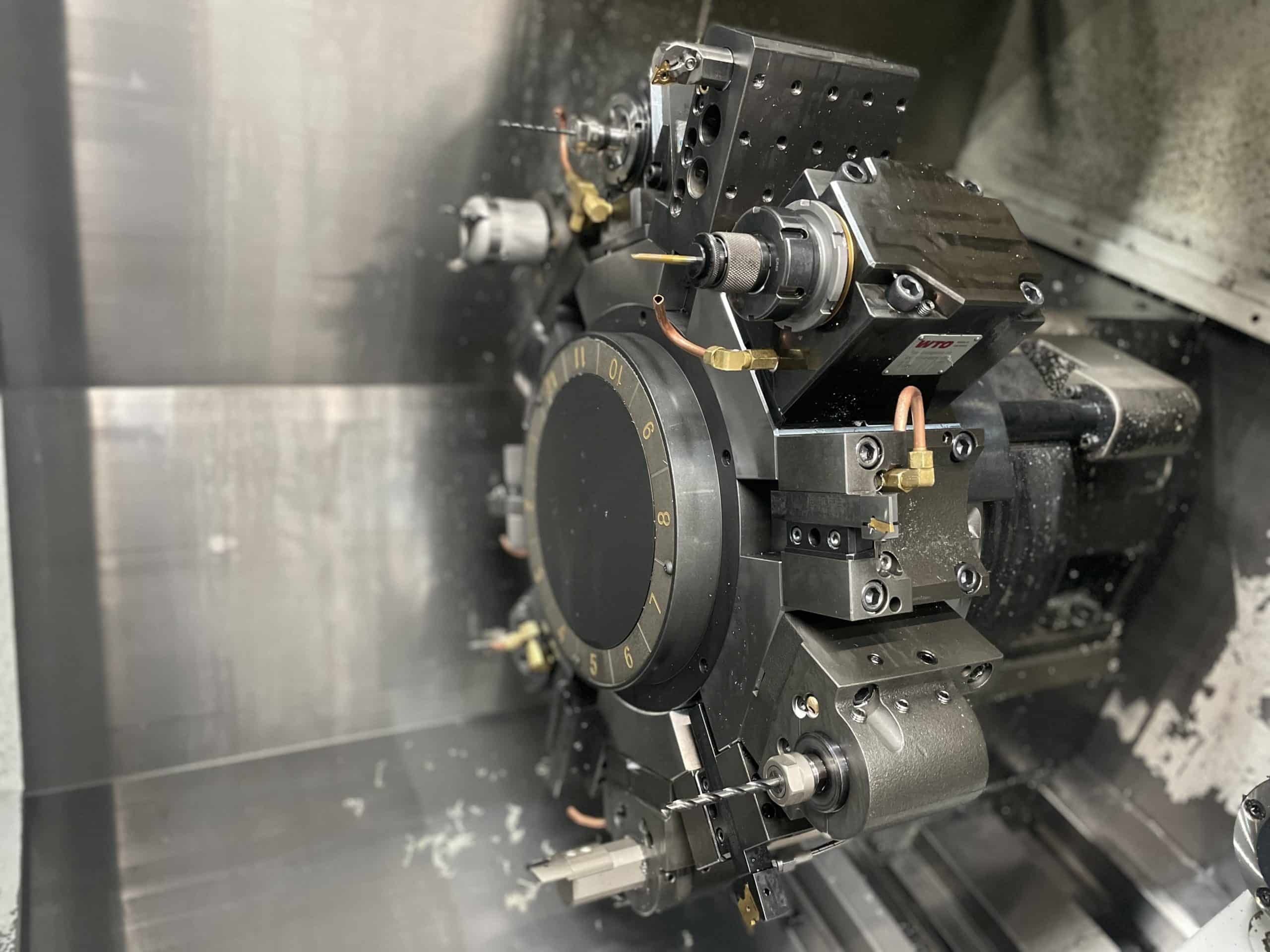

Turning

Turning is a precision machining process in which an operator rotates the workpiece on a lathe. Then the material is removed from the workpiece using cutting tools. A variety of materials can be machined using turning, including

- Metals

- Plastics

Turning creates cylindrical parts with smooth finishes. It is also possible to cut threads using a process called threading.

Vanderslice Machine Company's CNC machining services offer precision-turned parts for various applications. Our state-of-the-art turning equipment and experienced machinists allow us to produce parts with tight tolerances and smooth finishes. Contact us today for all your precision machining needs.

View CNC Turning Services

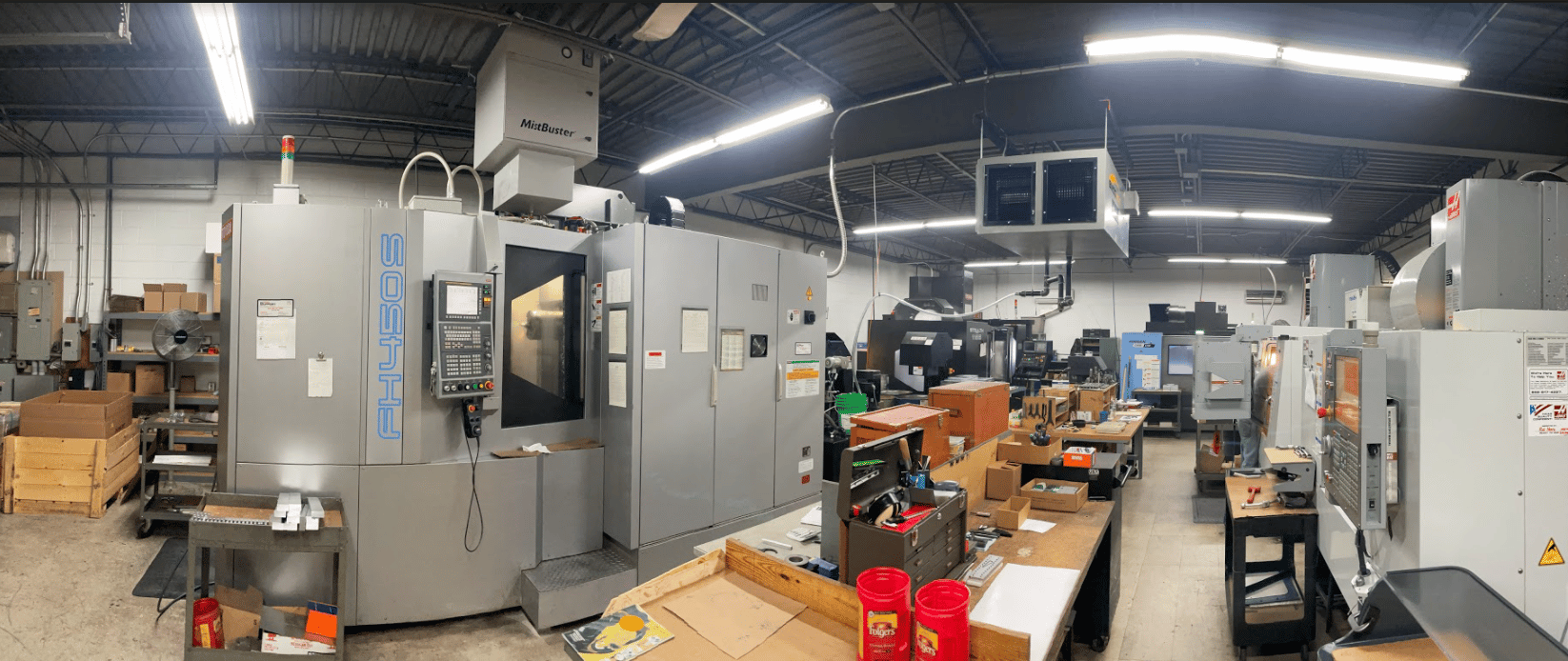

About Us

Vanderslice Machine Company is a high-precision machining company specializing in CNC precision machining parts. We are a family owned and operated machining service that has been in business for over 45 years.

Our company takes pride in our work and attention to detail. Our goal is to provide our customers with the highest quality products and services possible. In addition to our machining capabilities, we also offer a wide range of other services, such as support equipment, sub- contracting services, and raw materials manufacturing.

Whether you need a one-off custom part or a large production run, Vanderslice Machine Company is your go-to source for high-quality precision machined parts.

“Today, the company is owned and managed by the second and third generations”Precision is critical in machining processes

Vanderslice Machine Company is committed to providing the highest quality products and services possible. We specialize in machining parts for various aerospace, automotive, and medical industries.

Our state-of-the-art equipment and experienced machinists allow us to create CNC precision machined parts that meet or exceed our customers’ expectations. When you need CNC machining services, trust Vanderslice Machine Company to get the job done right.

Contact us today

Industries Served

Vanderslice Machine Company is proud to serve an array of industries such as the aerospace & defense, medical, linear motion, semiconductor, sensor equipment, and sports & recreation industries.

Support Equipment

- Horizontal Band Saw

- Vertical Band Saw

- Boyer Schultz 6” x 12” Surface Grinder

- Drill Presses

- Deburring/Tumbler

Additional Services

Additional services we offer include support equipment, sub-contracting services, and the manufacturing of raw materials such as steel, aluminum, brass/copper/bronze, plastic, stainless steel, titanium, and nickel alloys.

View All Additional Services